How to Determine the Right Borehole Size for Your Water Well Drilling Project

Selecting the correct borehole diameter is a make-or-break decision for your water well drilling project. An improperly sized borehole doesn’t just hurt efficiency—it leads to higher operational costs, reduced water yield, and even premature well failure.

At Zhengzhou Unique Drilling Rig Factory, we’ve helped thousands of clients optimize borehole sizes for residential, agricultural, municipal, and industrial projects. In this comprehensive guide, we’ll break down the key factors, standard sizes, technical calculations, and common mistakes to avoid—so you can choose a borehole size that balances water needs, geology, and equipment capabilities for long-term success.

What Are the Key Factors That Determine Borehole Diameter?

The right borehole size isn’t one-size-fits-all. It depends on three core pillars: your water demand, geological conditions, and equipment limitations. Let’s dive into each:

Water Demand Requirements

Your daily water needs directly dictate the minimum borehole diameter—because larger diameters equal higher yield potential. Here’s how to calculate it:

Estimated Daily Water Needs by Application:

Residential/domestic wells: For most households, the daily water consumption typically ranges from 150 to 300 gallons. This covers all essential daily needs such as drinking, cooking, laundry, bathing, and general household cleaning, with peak demand reaching 5 to 10 gallons per minute during heavy use.

Agricultural irrigation: Agricultural irrigation demands a large amount of water, usually 10,000–100,000+ gallons per day. The specific amount varies with crop types, planting acreage and climate, especially for water-intensive crops in arid areas, which often require higher water supply to ensure growth.

Municipal/community supply: Municipal and community water supply typically requires 50,000+ gallons per day, even reaching millions for larger areas. It serves residents, businesses, and public facilities, with the exact amount depending on the size of the population and local economic activity.

Industrial use: Industrial water consumption is highly variable, depending on manufacturing processes, cooling systems and production scales. Sectors like chemical, power and food processing differ greatly, with daily needs ranging from thousands to millions of gallons to sustain operations.

Every doubling of borehole diameter increases potential yield by 25–40%. Don’t just plan for current needs—add a 15–25% safety margin for future expansion

Geological Considerations–Don’t Ignore Your Soil/Rock

Geology dictates how your borehole is constructed—and thus its size. Ignoring formation type or aquifer characteristics is one of the biggest sizing mistakes.

Formation Type Impact:

Consolidated formations–rock: Require smaller diameters and may use open-hole completion

Unconsolidated formations–sand, gravel: Need larger diameters to accommodate screens and gravel packs

Mixed formations: May require telescoping designs for stability and yield.

Aquifer Characteristics:

Transmissivity: More permeable aquifers allow smaller diameters

Storage coefficient: Confined aquifers vs. unconfined aquifers affect drawdown—larger diameters reduce drawdown in low-yield aquifers

Depth to water: Deeper water tables need larger diameters to minimize pump wear and maintain consistent flow.

Equipment Limitations–Match Size to Your Drilling Rig

Your drill rig’s capabilities and casing availability will narrow down your options:

Drill rig capacity: Most rigs have a maximum practical diameter. Deeper wells often require smaller diameters due to rig constraints.

Casing availability: Standard casing sizes are more cost-effective and readily available. Custom sizes cost more and have longer lead times—so align your borehole size with standard casing.

What Are the Standard Borehole Sizes by Application?

To simplify your decision, here are the most common borehole and casing sizes for each use case—tested and trusted by drilling professionals worldwide:

Residential Water Wells

Residential wells prioritize cost-effectiveness and flexibility. Boreholes are typically 2–4 inches larger than casing to allow for installation and gravel packs.

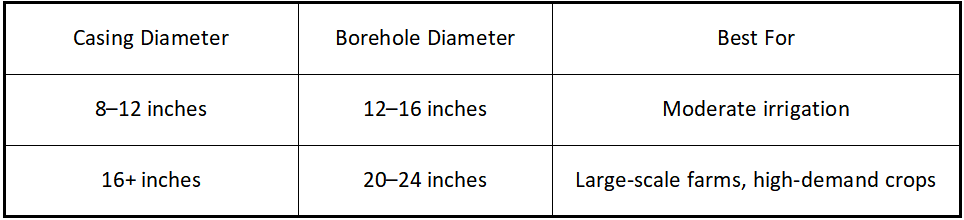

Agricultural Irrigation Wells

Irrigation requires high flow rates—so larger diameters are standard to accommodate big pumps and reduce entrance velocities.

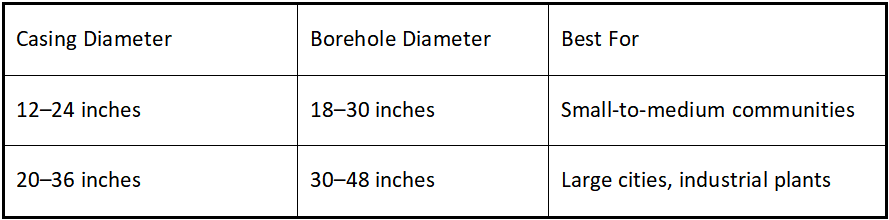

Municipal & Industrial Wells

These projects need massive volume—so boreholes are designed for heavy-duty pumps and long-term reliability.

How to Perform Technical Calculations for Borehole Sizing?

For precision, follow these technical steps to calculate your ideal borehole size. Focus on two critical metrics: screen entrance velocity and drawdown.

Hydraulic Calculations–Avoid Sand Pumping & Corrosion

The #1 rule for screen design: maximum entrance velocity = 0.1 feet per second. Exceeding this causes sand pumping and screen corrosion.

Drawdown Management

Drawdown is critical for marginal aquifers. Larger boreholes reduce drawdown by:

Increasing water storage in the well

Minimizing friction loss

Allowing deeper pump placement

Step-by-Step Sizing Process

A. Calculate peak demand: Convert daily needs to gallons per minute+15–25% safety margin.

B. Evaluate geology: Review aquifer test data, local drilling records, and formation samples.

C. Select casing diameter: Match to pump size and yield (use standard sizes for cost savings).

D. Calculate borehole diameter:

Add 2 inches minimum clearance for casing installation.

Add 4–8 inches if using a gravel pack.

Add extra inches for unstable formations.

E. Verify equipment compatibility: Confirm your drill rig can drill the diameter at depth.

What Special Considerations Are Needed for Complex Water Well Projects?

Gravel Pack Design

Gravel packs improve well efficiency and longevity by stabilizing formations and filtering sand. They require extra borehole space:

Add 4–8 inches to casing diameter,3–6 inch gravel thickness.

Choose gravel grain size based on formation.

Multi-Level Completions

For projects with multiple aquifers or water quality stratification:

Use a larger initial borehole (12–24 inches) to accommodate complex casing/screen designs.

Telescoping diameters (larger at the top, smaller at depth) save costs while maintaining performance.

Environmental Regulations

Local agencies often mandate:

Minimum casing diameters.

Annular space requirements for grouting to prevent contamination

Wellhead protection rules.

What Common Sizing Mistakes Should You Avoid in Water Well Drilling?

Undersizing for the future: Failing to plan for growth—like a growing family, expanded irrigation acreage, or new industrial processes—means you’ll face insufficient water later.

This forces costly re-drilling, a hassle that could’ve been avoided by simply upgrading your pump if the borehole was sized right initially.

Oversizing without justification: Larger boreholes mean significantly higher drilling costs, including more materials, longer working hours, and increased labor expenses, plus greater environmental impact like larger excavation ranges. Only opt for a bigger size when your water demand or geology truly requires it.

Ignoring local geology: Assuming a “standard” size works everywhere is extremely risky because different regions have vastly varying geological conditions. For instance, 6-inch boreholes often lead to collapses, insufficient water yield, or even complete project failure when used in loose sand.

Ignoring drilling rig limits: Specifying a 12-inch borehole for a water well drilling rig that only drills 8 inches is a costly error. The rig can’t fulfill the demand, causing project halts, rework on designs, and extra fees for renting or purchasing a suitable water well drilling rig—all of which wastes valuable time and money.

Why Does Professional Consultation Matter for Borehole Sizing?

While this guide offers a solid framework for borehole sizing, complex projects like industrial wells or those with mixed geology involve unique challenges that demand professional insights. To ensure accuracy and avoid costly mistakes, we recommend the following expert-driven steps:

Consulting a professional hydrogeologist for aquifer testing is crucial. These experts use on-site surveys and scientific methods to assess permeability and water storage capacity, providing accurate data to avoid blind sizing decisions.

Reviewing successful well designs in your area is a practical step. Local drillers, who know the regional geology best through years of on-site experience, have proven designs that align with local soil and rock conditions, helping you avoid unnecessary risks.

Conclusion

Choosing the right borehole size is about balance: meet current demand, adapt to future needs, and work with your geology/equipment. Remember: larger isn’t always better—just right is better.

At Zhengzhou Unique Drilling Rig Factory, we specialize in manufacturing drilling rigs that match every borehole size requirement—from residential 8-inch boreholes to industrial 48-inch boreholes. Our technical team provides personalized sizing support, and our rigs are built for durability and efficiency.